Once it has been determined that a Screw Conveyor will best fit your application, and the type of screw conveyor you will use (shafted or shaftless), a calculation will be completed to specify the horsepower that will be needed to meet the needs of the application. Simply put, horsepower is a measure of the rate at which work is done. In the case of the screw conveyor it is a measure of the power needed to move the material in question a defined distance and elevation.

Screw conveyor horsepower requirements are directly defined in the CEMA Standard No. 350 – Screw Conveyor for Bulk Materials. To calculate the horsepower needs for a given application it is first important to understand the needs of the application. This includes the mass flow rate requirements in lbs/hr, the bulk density in lbs/ft3, the length of the conveyor in ft, and whether this will be a batch or constant application, and horizontal or inclined conveyor, and the safety factor desired. The operating speed to carry the required amount of material in RPM must also be calculated.

A conveyor with horsepower that is undersized for the application will not be able to convey the material, will certainly not be able to handle any “slugs” or unexpected volume of material, and may result in motor failure and loss of productivity. One that is oversized will use more power than needed and have excessive costs.

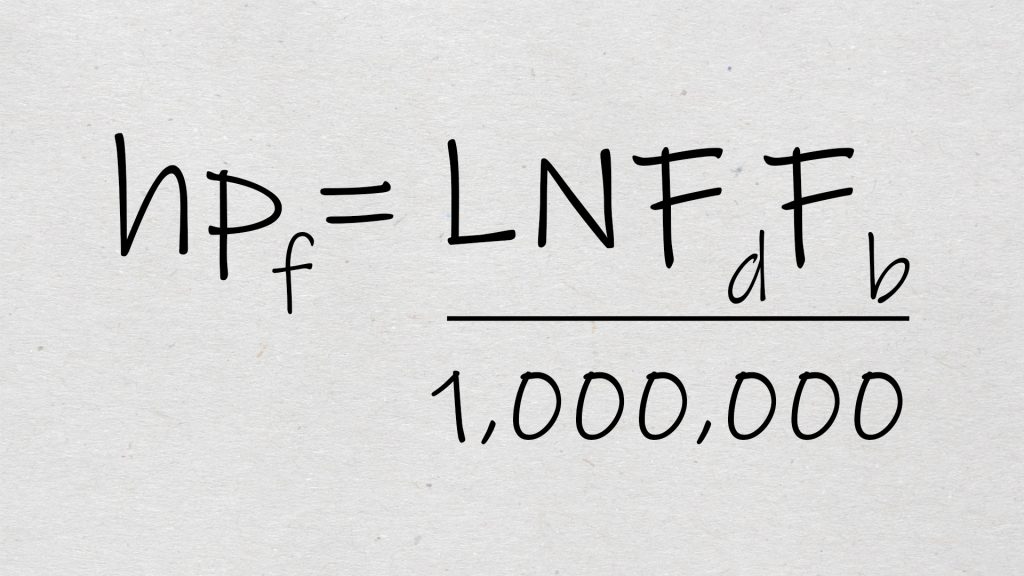

Two components make up the horsepower requirements, first is the hpf, the horsepower needed to overcome friction, and second is the hpm or horsepower needed to convey the material. Hpf represents the horsepower needed to turn, overcoming friction, the empty equipment and is affected by the conveyor length, speed, and factors that represent the resistance of the hanger bearings and screw diameter. These factors have been predetermined by analysis of data and are published by CEMA.

L= Total Length (ft)

N= Operating Speed (rpm)

Fd= Screw Diameter Factor (CEMA Table 3.2)

Fb= Hanger Bearing Factor (CEMA Table 3.1)

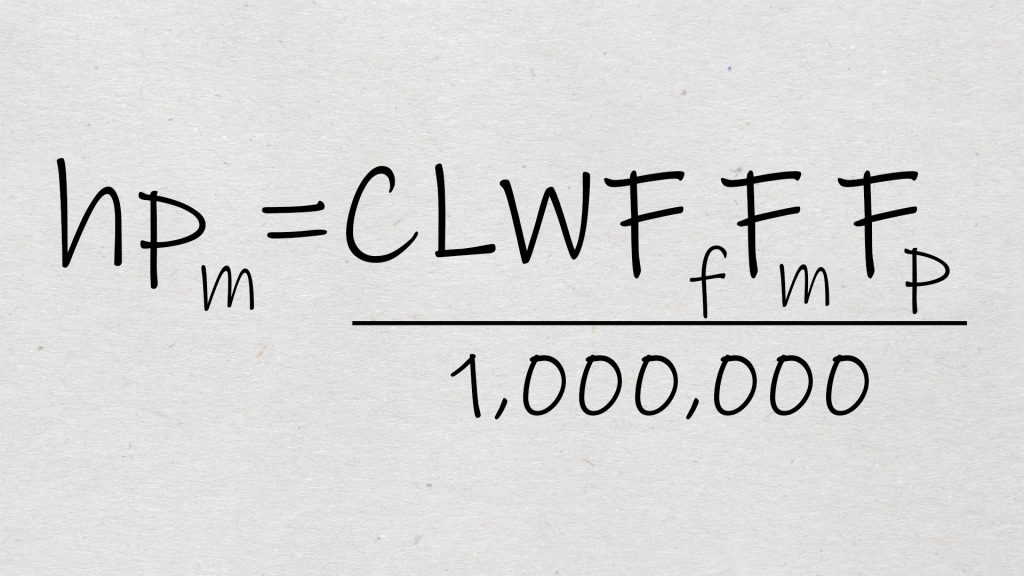

Hpm is affected by such things as the capacity and length, and material density. These are independent variables determined by the location and process.

C= Capacity (ft3/hr)

W= Density of Material as Conveyed (lbs/ft3)

Ff= Flight Factor (CEMA Table 3.3)

Fm= Material Factor

Fp= Paddle Factor (CEMA Table 3.4)

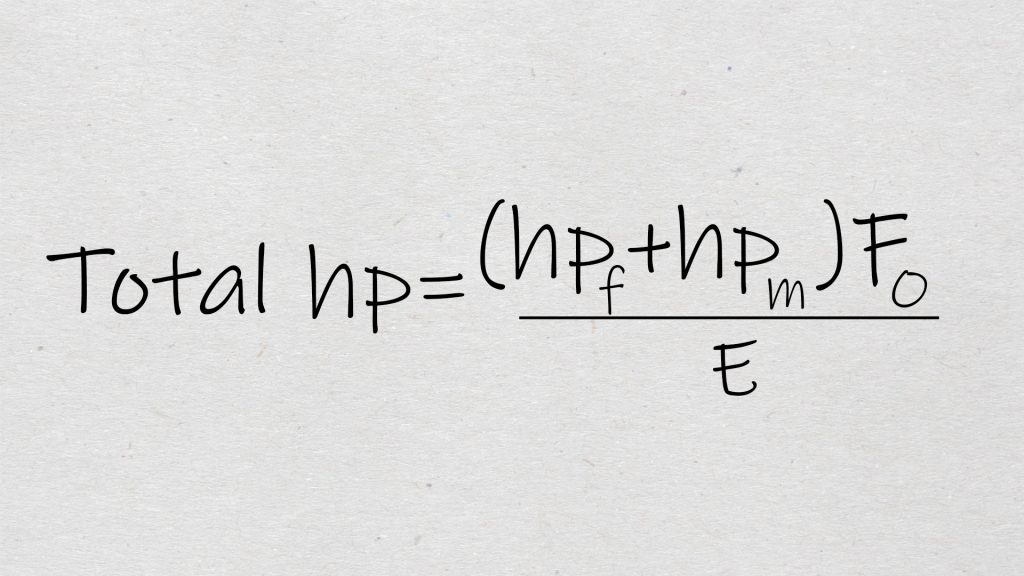

The total horsepower requirement is calculated as the sum of these two factors allowing for an overload factor and the overall drive efficiency.

E= Drive Efficiency (CEMA Table 8.1)

Fo= Overload Factor (CEMA Figure 3.1)

Hence you have the required horsepower for the conveyor in question. It is important to note that all of the components of the screw conveyor must be sized to handle the full motor horsepower. Your conveyor supplier will help you in determining the right conveyor and the horsepower needed for your application.

*Reference CEMA Standard No. 350 Screw Conveyor for Bulk Materials

Andrew Gaiser is employed in the JMS Engineering Department in the role of Product Engineer. Andrew is a graduate of Virginia Tech in Mechanical Engineering, and has had previous experience in design at Controls Southeast Inc. As a former competitive runner, he is still an avid runner and also enjoys rock climbing.